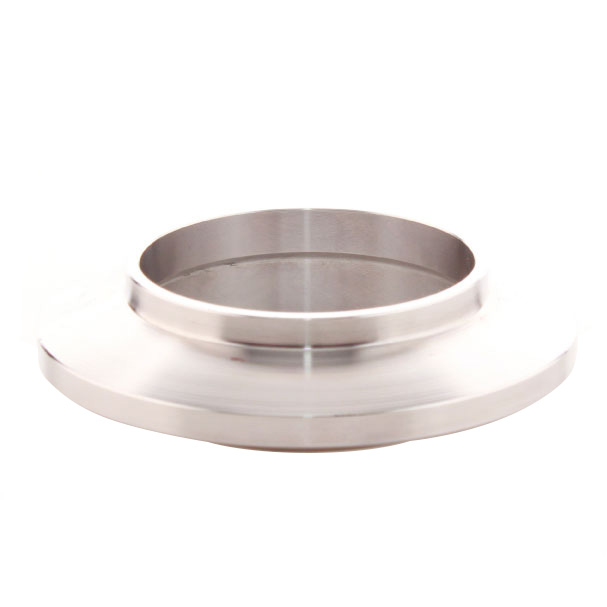

Certification, quality management system

All our production processes are certified. We care about the highest quality of processing and consistent quality control for all our products.

We have a quality system with all the modern methods for checking the quality of the entire production process, from purchasing material through continuous production control to final inspection before shipment.

- certificate of quality management system according to ISO 9001: 2008

- certificate of quality management system according to TS 16949: 2009

- certificate of quality management system according to VDA 6.1: 2010

- certificate of enviroment management system according ISO 14001: 2004

In an effort to provide for our customers technically perfect product, we are working with a minimal defect strategy.